BeMetals Announces Substantial Increase to Mineral Resource at the High-Grade South Mountain Zinc-Silver-Gold-Copper Project in Idaho

May 4, 2021

VANCOUVER, CANADA - BeMetals Corp. (TSXV: BMET, OTCQB: BMTLF, Frankfurt: 1OI.F) (the “Company” or “BeMetals) is pleased to announce an updated Mineral Resource Estimate (“MRE”) incorporating results from its Phases 1 and 2 underground diamond drilling programs at the South Mountain Project (“South Mountain” or “South Mountain Project” or the “Property”) in southwestern Idaho, U.S.A. The updated MRE includes a substantially increased resource for the Project while maintaining the high-grade nature of the mineralization.

The updated Independent MRE, which has an effective date of April 20, 2021, was prepared in accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI-43-101”) by Hard Rock Consulting, LLC, based in the U.S.A. More details are included in Tables 1 & 2 below and a technical report for this MRE will be filed with SEDAR and on the Company’s website within 45 days from the date of this news release.

HIGHLIGHTS OF UPDATED MINERAL RESOURCE

- Measured & Indicated (“M&I”): 187,650 tonnes grading 9.63% Zinc (“Zn”), 151 grams per tonne (“g/t”) Silver (“Ag”), 2.19 g/t Gold (“Au”), 1.01% Lead (“Pb”) and 0.63% Copper (“Cu”).

- This represents a 21.8% increase to the M&I tonnage from the historical 2019 MRE with a 20.36% Zn equivalent grade (“ZnEq”).

- Inferred: 756,300 tonnes grading 7.63% Zn, 196 g/t Ag, 1.40 g/t Au, 0.97% Pb and 0.81% Cu.

- This represents a 129.5% increase in the Inferred tonnage from the historical 2019 MRE with a 18.10% ZnEq.

Note: See Table 1 and 2 footnotes section 4 for details of the Zn equivalent grade calculation

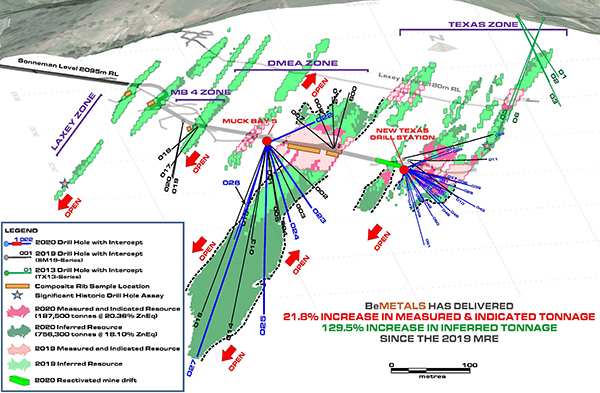

John Wilton, President and CEO of BeMetals stated, “We are very pleased with the results of this updated mineral resource estimate, more than doubling the high-grade inferred resources at the South Mountain deposit. BeMetals has delivered on its objective of substantially increasing the resource base at the Project while maintaining the high-grade nature of the mineralization at 20.36% and 18.10% zinc equivalent grade for M&I and Inferred resource categories respectively. This has been achieved predominantly through the successful expansion of the DMEA Zone and with additional tonnage at the Texas West and East Zones (See Figure 1). Importantly, all of these zones and other known areas of mineralization remain open to further increase with future underground drilling.

The data collected from the drilling campaigns have confirmed the robust and extensive high-grade of the South Mountain deposit’s mineralization. The experienced project team based in Boise, Idaho, which includes personnel from both BeMetals and Thunder Mountain Gold Inc., (the optionee of the Property), completed the successful underground drilling programs on time and on budget. Given the success of our work to date, we are confident that with more drilling during future phases of evaluation, the South Mountain mineral resource base can be further expanded. The results of today’s MRE will be incorporated into the ongoing South Mountain Preliminary Economic Assessment (“PEA”), which is planned for completion in September this year.”

MINERAL RESOURCE ESTIMATE

In two phases of drilling during 2019 and 2020, a combined total of approximately 5,000 metres of underground core drilling was completed at South Mountain. During these drilling campaigns, our site team also widened and advanced the existing Sonneman level eastwards by some 52 metres to establish a new drill station closer to the Texas Zone. All the results of this drilling have now been in incorporated into the updated MRE for the South Mountain deposit.

Tables 1 & 2 below provide the Mineral Resource Statement for the Project in metric and U.S. units respectively with details of the modelling methodology and cut-off grades applied to the mineral resource. Figure 1 illustrates the principal areas where the South Mountain deposit has been expanded from the historical MRE that was completed in 2019. The historical Technical Report for the Mineral Resource Estimate for the South Mountain Project Owyhee County, Idaho USA Report Date: Dated: April 1, 2019 is filed on SEDAR.

Table 1. South Mountain Mineral Resource Statement (Metric Units)

| Grades and Contained Metal | |||||||||||||

| Ore Type | Classification | Mass | Zinc | Zinc | Silver | Silver | Gold | Gold | Lead | Lead | Copper | Copper | ZnEq |

| kt | % | t | ppm | kg | ppm | g | % | t | % | t | % | ||

| Massive Sulfide | Measured | 48.85 | 11.45 | 5,600 | 126 | 6,100 | 2.38 | 116,200 | 0.79 | 400.00 | 0.46 | 200 | 20.21 |

| Indicated | 107.90 | 11.36 | 12,300.0 | 164 | 17,700 | 2.63 | 283,500 | 1.36 | 1,500 | 0.53 | 600 | 22.14 | |

| Measured + Indicated | 156.75 | 11.39 | 17,800.0 | 152 | 23,800 | 2.55 | 399,700 | 1.18 | 1,900 | 0.51 | 800 | 21.54 | |

| Inferred | 705.03 | 8.09 | 57,000.0 | 202 | 142,600 | 1.49 | 1,049,000 | 1.04 | 7,300 | 0.74 | 5,200 | 18.34 | |

| Skarn | Measured | 9.62 | 1.25 | 100.0 | 187 | 1,800 | 0.78 | 7,500 | 0.30 | 0 | 1.26 | 100 | 18.23 |

| Indicated | 21.28 | 0.49 | 100.0 | 130 | 2,800 | 0.17 | 3,700 | 0.07 | 0 | 1.20 | 300 | 12.63 | |

| Measured + Indicated | 30.90 | 0.72 | 200.0 | 148 | 4,600 | 0.36 | 11,200 | 0.14 | 0 | 1.21 | 400 | 14.38 | |

| Inferred | 51.26 | 1.34 | 700.0 | 110 | 5,600 | 0.19 | 9,900 | 0.04 | 0 | 1.66 | 900 | 14.92 | |

| Total | Measured | 58.47 | 9.77 | 5,700.0 | 136 | 7,900 | 2.12 | 123,700 | 0.71 | 400 | 0.59 | 300 | 19.88 |

| Indicated | 129.18 | 9.57 | 12,400.0 | 158 | 20,400 | 2.22 | 287,300 | 1.15 | 1,500 | 0.64 | 800 | 20.57 | |

| Measured + Indicated | 187.65 | 9.63 | 18,100.0 | 151 | 28,400 | 2.19 | 411,000 | 1.01 | 1,900 | 0.63 | 1,200 | 20.36 | |

| Inferred | 756.30 | 7.63 | 57,700.0 | 196 | 148,200 | 1.40 | 1,058,900 | 0.97 | 7,300 | 0.81 | 6,100 | 18.10 | |

- The effective date of the mineral resource estimate is April 20th, 2021. The QP for the estimate is Mr. Richard A. Schwering, P.G., SME-RM, of Hard Rock Consulting, LLC. and is independent of BeMetals, Corp., Thunder Mountain Gold Inc., and South Mountain Mines Inc.

- Mineral resources are not mineral reserves and do not have demonstrated economic viability such as diluting materials and allowances for losses that may occur when material is mined or extracted; or modifying factors including but not restricted to mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors. Inferred mineral resources may not be converted to mineral reserves. It is reasonably expected, though not guaranteed, that the majority of Inferred mineral resources could be upgraded to Indicated mineral resources with continued exploration.

- The mineral resource is reported at an underground mining cutoff of $102.5 U.S. Net Smelter Return (“NSR”) within coherent wireframe models. The NSR calculation and cut-off is based on the following assumptions: an Au price of $1,750/oz, Ag price of $23.00/oz, Pb price of $1.02/lb., Zn price of $1.20/lb. and Cu price of $3.40/lb.; Massive sulfide ore type metallurgical recoveries and payables of 52.25% for Au, 71.25% for Ag, 71.40% for Zn, 66.50% for Pb, and 49.00% for Cu and a total smelter cost of $33.29; Skarn ore type metallurgical recoveries and payables of 71.25% for Au, 80.75% for Ag, 51.00% for Zn, 47.50% for Pb, and 87.70% for Cu and a smelter cost of $7.24; assumed mining cost of $70/ton, process costs of $25/ton, and general and administrative costs of $7.5/ton. Based on the stated prices and recoveries the NSR formula is calculated as follows; NSR = (Ag grade * Ag price * Ag Recovery and Payable) + (Au grade * Au price * Au Recovery and Payable) + (Pb grade * 20 * Pb Price * Pb Recovery and Payable) + (Cu grade * 20 * Cu Price * Cu Recovery and Payable) + (Zn grade * 20 * Zn Price * Zn Recovery and Payable) for each ore type.

- The zinc equivalent grades were calculated as Zn Grade + (((Pb Price * Pb Recovery and Payable) / (Zn Price*Zn Recovery and Payable)) * Pb Grade) + (((Cu Price * Cu Recovery and Payable) / (Zn Price * Zn Recovery and Payable)) * Cu Grade) + (((Ag Price * Ag Recovery and Payable) / (Zn Price * 20 * Zn Recovery and Payable)) * Ag Grade) + (((Au Price * Au Recovery and Payable) / (Zn Price * 20 * Zn Recovery and Payable)) * Au Grade)

- Rounding may result in apparent differences when summing tons, grade and contained metal content. Tonnage and grade measurements are in U.S. units and converted to metric

Table 2. Table 2 South Mountain Mineral Resource Statement (U.S. Units)

| Grades and Contained Metal | |||||||||||||

| Ore Type | Classification | Mass | Zinc | Zinc | Silver | Silver | Gold | Gold | Lead | Lead | Copper | Copper | ZnEq |

| thousand sh. ton | % | thousand lb | t. oz/sh. ton | thousand t. oz | t. oz/sh. ton | thousand t. oz | % | thousand lb | % | thousand lb | % | ||

| Massive Sulfide | Measured | 53.8 | 11.45 | 12,300 | 3.67 | 197 | 0.069 | 3.7 | 0.79 | 900 | 0.46 | 500 | 20.21 |

| Indicated | 118.9 | 11.36 | 27,000 | 4.77 | 568 | 0.077 | 9.1 | 1.36 | 3,200 | 0.53 | 1,300 | 22.14 | |

| Measured + Indicated | 172.8 | 11.39 | 39,300 | 4.43 | 765 | 0.074 | 12.9 | 1.18 | 4,100 | 0.51 | 1,800 | 21.54 | |

| Inferred | 777.2 | 8.09 | 125,700 | 5.90 | 4,586 | 0.043 | 33.7 | 1.04 | 16,100 | 0.74 | 11,500 | 18.34 | |

| Skarn | Measured | 10.6 | 1.25 | 300 | 5.46 | 58 | 0.023 | 0.2 | 0.30 | 100 | 1.26 | 300 | 18.23 |

| Indicated | 23.5 | 0.49 | 200 | 3.78 | 89 | 0.005 | 0.1 | 0.07 | 0 | 1.20 | 600 | 12.63 | |

| Measured + Indicated | 34.1 | 0.72 | 500 | 4.30 | 147 | 0.011 | 0.4 | 0.14 | 100 | 1.21 | 800 | 14.38 | |

| Inferred | 56.5 | 1.34 | 1,500 | 3.19 | 181 | 0.006 | 0.3 | 0.04 | 100 | 1.66 | 1,900 | 14.92 | |

| Total | Measured | 64.5 | 9.77 | 12,600 | 3.96 | 255 | 0.062 | 4.0 | 0.71 | 900 | 0.59 | 800 | 19.88 |

| Indicated | 142.4 | 9.57 | 27,200 | 4.61 | 656 | 0.065 | 9.2 | 1.15 | 3,300 | 0.64 | 1,800 | 20.57 | |

| Measured + Indicated | 206.9 | 9.63 | 39,800 | 4.41 | 912 | 0.064 | 13.2 | 1.01 | 4,200 | 0.63 | 2,600 | 20.36 | |

| Inferred | 833.7 | 7.63 | 127,300 | 5.72 | 4,766 | 0.041 | 34.0 | 0.97 | 16,200 | 0.81 | 13,400 | 18.10 | |

- The effective date of the mineral resource estimate is April 20th, 2021. The QP for the estimate is Mr. Richard A. Schwering, P.G., SME-RM, of Hard Rock Consulting, LLC. and is independent of BeMetals Corp., Thunder Mountain Gold Inc., and South Mountain Mines Inc.

- Mineral resources are not mineral reserves and do not have demonstrated economic viability such as diluting materials and allowances for losses that may occur when material is mined or extracted; or modifying factors including but not restricted to mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors. Inferred mineral resources may not be converted to mineral reserves. It is reasonably expected, though not guaranteed, that the majority of Inferred mineral resources could be upgraded to Indicated mineral resources with continued exploration.

- The mineral resource is reported at an underground mining cutoff of $102.5 U.S. Net Smelter Return (“NSR”) within coherent wireframe models. The NSR calculation and cut-off is based on the following assumptions: an Au price of $1,750/oz, Ag price of $23.00/oz, Pb price of $1.02/lb., Zn price of $1.20/lb. and Cu price of $3.40/lb.; Massive Sulfide ore type metallurgical recoveries and payables of 52.25% for Au, 71.25% for Ag, 71.40% for Zn, 66.50% for Pb, and 49.00% for Cu and a total smelter cost of $33.29; Skarn ore type metallurgical recoveries and payables of 71.25% for Au, 80.75% for Ag, 51.00% for Zn, 47.50% for Pb, and 87.70% for Cu and a smelter cost of $7.24; assumed mining cost of $70/ton, process costs of $25/ton, and general and administrative costs of $7.5/ton. Based on the stated prices and recoveries the NSR formula is calculated as follows; NSR = (Ag grade * Ag price * Ag Recovery and Payable) + (Au grade * Au price * Au Recovery and Payable) + (Pb grade * 20 * Pb Price * Pb Recovery and Payable) + (Cu grade * 20 * Cu Price * Cu Recovery and Payable) + (Zn grade * 20 * Zn Price * Zn Recovery and Payable) for each ore type.

- The zinc equivalent grades were calculated as Zn Grade + (((Pb Price * Pb Recovery and Payable) / (Zn Price*Zn Recovery and Payable)) * Pb Grade) + (((Cu Price * Cu Recovery and Payable) / (Zn Price * Zn Recovery and Payable)) * Cu Grade) + (((Ag Price * Ag Recovery and Payable) / (Zn Price * 20 * Zn Recovery and Payable)) * Ag Grade) + (((Au Price * Au Recovery and Payable) / (Zn Price * 20 * Zn Recovery and Payable)) * Au Grade)

- Rounding may result in apparent differences when summing tons, grade and contained metal content. Tonnage and grade measurements are in U.S. units.

Figure 1: 3D Perspective view inclined 200 looking north-north-east, indicating the areas of the expanded mineral resource compared to the 2019 MRE

QUALIFIED PERSON STATEMENT FOR THE MINERAL RESOURCE ESTIMATE

Mr. Richard A. Schwering, P.G., SME-RM, a Resource Geologist with Hard Rock Consulting, LLC, is responsible for the South Mountain Project Mineral Resource Estimate with an effective date of April 20, 2021. Mr. Schwering is a Qualified Person as defined by NI43-101 and is independent of BeMetals Corp., Thunder Mountain Mines Inc., and South Mountain Mines, Inc. Mr. Schwering estimated the mineral resources based on drill hole and channel sample data constrained by geologic boundaries using an Ordinary Krige algorithm. The Geologic Model and Mineral Resource Estimate were completed using Leapfrog Geo® Software version 6.0.5.

ADDITIONAL RECENT DRILLING RESULTS INCLUDED WITHIN THE UPDATED MRE

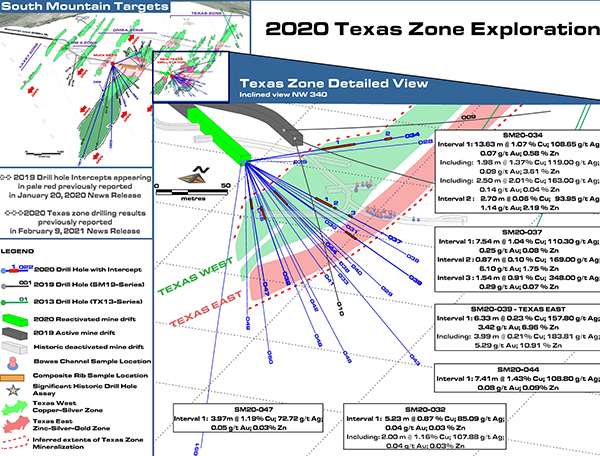

The Company also reports further drilling results from both the Texas East and Texas West Zones. This new data supports previously reported results (See BMET news release dated, February, 9, 2021), illustrating the high-grade zinc-silver-gold nature of the Texas East mineralization, and generally copper-silver dominant Texas West Zone.

Figure 2 shows the location of drill holes; SM20-032, SM20-034, SM20-037, SM20-039, SM20-044, SM20-047 in the Texas East and Texas West Zones. Table 3 below indicates the details of these drilling results. All drilling results from the Phase 1 & 2 programs have now been incorporated into the MRE.

Figure 2: 3D Perspective view inclined 200 looking north-north-east, with hole locations for SM20-032, SM20-034, SM20-037, SM20-039 - SM20-044, SM20-047

Table 3 below indicates the drilling results received from both the Texas East and Texas West Zones.

Table 3. Analytical and Assay Results From Texas East Zone

| Drill Hole ID, Zone & Interval |

From (m) |

To (m) |

Core Interval (m) | Zn % | Ag g/t |

Au g/t |

Pb % | Cu % |

| TEXAS ZONE | ||||||||

| Texas East | ||||||||

| SM20-039 | 65.76 | 72.09 | 6.33 | 6.96 | 157.80 | 3.42 | 2.08 | 0.23 |

| Including | 65.76 | 69.75 | 3.99 | 10.91 | 183.81 | 5.29 | 3.14 | 0.21 |

Note: Reported widths are drilled core lengths as true widths are unknown at this time. It is estimated based upon current data that true widths might range between 60-80% of the drilled intersection. Intervals cut offs are based upon visual contacts of massive sulphide units with no more than 1.68 metres of internal skarn. Table 5 below documents; Drill Hole Azimuth, Dip, end of hole length, and Collar Co-ordinates (Note: See details below in QA/QC section).

Table 4. Analytical and Assay Results From Texas West Zone

| Drill Hole ID, Zone & Interval |

From (m) |

To (m) |

Core Interval (m) | Cu % | Ag g/t |

Au g/t |

Pb % | Zn % |

| TEXAS ZONE | ||||||||

| Texas West | ||||||||

| SM20-032 | 19.23 | 24.46 | 5.23 | 0.87 | 85.09 | 0.04 | 0.02 | 0.03 |

| Including | 22.46 | 24.46 | 2.00 | 1.16 | 107.88 | 0.04 | 0.03 | 0.03 |

| SM20-034 | ||||||||

| Interval 1: | 31.85 | 45.48 | 13.63 | 1.07 | 108.65 | 0.07 | 0.04 | 0.58 |

| Including | 34.96 | 36.94 | 1.98 | 1.37 | 119.00 | 0.09 | 0.04 | 3.61 |

| Including | 39.56 | 42.06 | 2.50 | 2.01 | 163.00 | 0.14 | 0.03 | 0.04 |

| Interval 2: | 57.96 | 60.66 | 2.70* | 0.06 | 93.95 | 1.14 | 0.66 | 2.19 |

| SM20-037 | ||||||||

| Interval 1: | 33.76 | 41.30 | 7.54 | 1.04 | 110.30 | 0.25 | 0.02 | 0.08 |

| Interval 2: | 42.50 | 43.37 | 0.87† | 0.10 | 169.00 | 6.10 | 1.19 | 1.75 |

| Interval 3: | 49.53 | 51.07 | 1.54 | 0.91 | 348.00 | 0.29 | 0.29 | 0.07 |

| SM20-044 | 17.37 | 24.78 | 7.41 | 1.43 | 108.80 | 0.08 | 0.02 | 0.09 |

| SM20-047 | 16.76 | 20.73 | 3.97 | 1.19 | 72.72 | 0.05 | 0.00 | 0.03 |

Note: Reported widths are drilled core lengths as true widths are unknown at this time. It is estimated based upon current data that true widths might range between 60-80% of the drilled intersection. A nominal cut-off grade of 0.5% Cu has been applied to determine the boundaries of the intersections for this skarn-hosted mineralization with no more than 4.46 metres of internal dilution. *A nominal cut-off grade of 1% Zn has been applied to this intersection. † Denotes single sample. Table 5 below documents; Drill Hole Azimuth, Dip, end of hole length, and Collar Co-ordinates (Note: See details below in QA/QC section).

Table 5: Drill Hole Azimuth, Dip, End of hole length and Collar Co-ordinates

| Hole ID | Azimuth Degree | Dip Degree | End of hole Length (m) | East (ft.) | North (ft.) | Elevation (ft.) |

| SM20-032 | 104.79 | -64.33 | 43.89 | 2311763.6 | 393645.3 | 6866.77 |

| SM20-034 | 79.33 | 15.06 | 66.14 | 2311763.6 | 393645.3 | 6866.77 |

| SM20-037 | 99.99 | -14.09 | 68.64 | 2311763.6 | 393645.3 | 6866.77 |

| SM20-039 | 122.39 | -7.95 | 106.68 | 2311763.6 | 393645.3 | 6866.77 |

| SM20-044 | 74.01 | -44.98 | 46.94 | 2311763.6 | 393645.3 | 6866.77 |

| SM20-047 | 60.14 | -79.87 | 52.88 | 2311763.6 | 393645.3 | 6866.77 |

QUALITY ASSURANCE AND QUALITY CONTROL PROCEDURES

The project employs a rigorous QC/QA program that includes; blanks, duplicates and appropriate certified standard reference material. All samples are introduced into the sample stream prior to sample handling/crushing to monitor analytical accuracy and precision. The insertion rate for the combined QA/QC samples is 10 percent or more depending upon batch sizes. ALS Global completed the analytical work with the core samples processed at their preparation facility in Reno, Nevada, U.S.A. All analytical and assay procedures are conducted in the ALS facility in North Vancouver, BC. The samples are processed by the following methods as appropriate to determine the grades; Au-AA23-Au 30g fire assay with AA finish, ME-ICP61-33 element four acid digest with ICP-AES finish, ME-OG62-ore grade elements, four acid with ICP-AES finish, Pb-OG62-ore grade Pb, four acid with ICP-AES finish, Zn-OG62-ore grade Zn, four acid digest with ICP-AES finish, Ag-GRA21-Ag 30g fire assay with gravimetric finish.

ABOUT THE SOUTH MOUNTAIN PROJECT

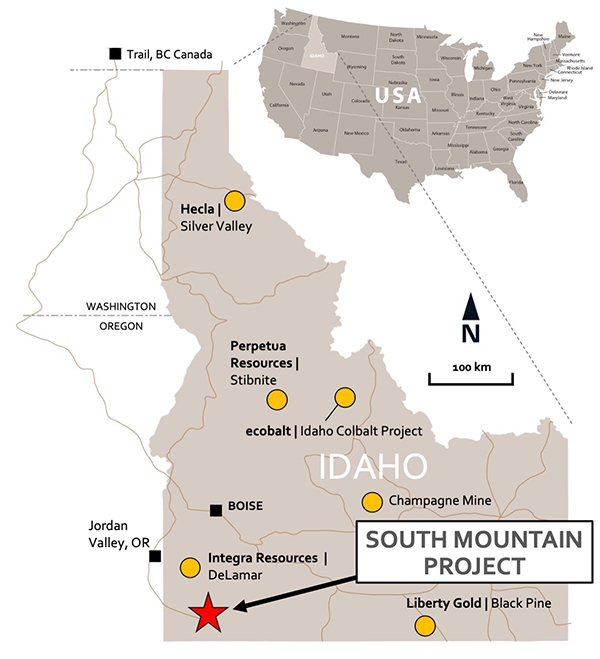

South Mountain is a polymetallic development project focused on high-grade zinc and is located approximately 70 miles southwest of Boise, Idaho (See Figure 3). The Project was intermittently mined from the late 1800s to the late 1960s and its existing underground workings remain intact and well maintained. Historic production at the Project has largely come from high-grade massive sulphide bodies that remain open at depth and along strike. According to historical smelter records, approximately 53,642 tons of mineralized material has been mined to date. These records also indicate average grades; 14.5% Zn, 363.42 g/t Ag, 1.98 g/t Au, 2.4% Pb, and 1.4% Cu were realised (See NI 43-101 Technical Report: Updated Mineral Resource Estimate for the South Mountain Project, dated May 6, 2019, Section 6.4 – Table 6.4 for more details. Available on the BeMetals website and at www.sedar.com). Thunder Mountain Gold Inc. purchased and advanced the project from 2007 through 2019, with expenditures into the project of approximately US$12million.

BeMetals formed a Boise, Idaho-based project team that is focused on advancing South Mountain. This team includes key management of Thunder Mountain Gold Inc., Optionee of the Property. The project team has completed re-establishment of the Project site and have conducted two phases of drilling. The team continues to build and maintain strong relations with local communities relevant to the South Mountain Project. The Project is largely on and surrounded by private surface land, and as such, the permitting and environmental aspects of the Project are expected to be straightforward. Permits are in place for underground exploration activities and BeMetals does not anticipate significant barriers to any future development at the Project.

Figure 3: Project Location Map

ABOUT BEMETALS CORP.

BeMetals is a precious and base metals exploration and development company focused on becoming a leading metal producer through the acquisition of quality exploration, development and potentially production stage projects. The Company has recently established itself in the gold sector with the acquisition of certain wholly owned exploration projects in Japan. BeMetals is also progressing both its advanced high-grade, zinc-silver-gold-copper polymetallic underground exploration at the South Mountain Project in Idaho through a preliminary economic assessment, and its tier-one targeted, Pangeni Copper Exploration Project in Zambia. Guiding and leading BeMetals’ growth strategy is a strong board and management team, founders and significant shareholders of the Company, who have an extensive proven record of delivering considerable value in the mining sector through the discovery, construction and operation of mines around the world.

The technical information in this news release for BeMetals has been reviewed and approved by John Wilton, CGeol FGS, CEO and President of BeMetals, and a “Qualified Person” as defined under National Instrument 43-101.

ON BEHALF OF BEMETALS CORP.

"John Wilton"

John Wilton

President, CEO and Director

For further information about BeMetals please visit our website at www.bemetalscorp.com and sign-up to our email list to receive timely updates, or contact:

Derek Iwanaka

Vice President, Investor Relations & Corporate Development

Telephone: 604-609-6141

Email: diwanaka@bemetalscorp.com

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX

Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Note Regarding Forward-Looking Statements

This news release contains "forward-looking statements" and “forward looking information” (as defined under applicable securities laws), based on management’s best estimates, assumptions and current expectations. Such statements include but are not limited to, statements with respect to future exploration, development and advancement of the South Mountain Project, the Pangeni project and the Japan properties, and the acquisition of additional base and/or precious metal projects. Generally, these forward-looking statements can be identified by the use of forward-looking terminology such as "expects", "expected", "budgeted", "forecasts", "anticipates", "plans", "anticipates", "believes", "intends", "estimates", "projects", "aims", "potential", "goal", "objective", "prospective", and similar expressions, or that events or conditions "will", "would", "may", "can", "could" or "should" occur. These statements should not be read as guarantees of future performance or results. Such statements involve known and unknown risks, uncertainties and other factors that may cause actual results, performance or achievements to be materially different from those expressed or implied by such statements, including but not limited to: the actual results of exploration activities, the availability of financing and/or cash flow to fund the current and future plans and expenditures, the ability of the Company to satisfy the conditions of the option agreements for the South Mountain Project and/or the Pangeni Project, and changes in the world commodity markets or equity markets. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. The forward-looking statements and forward looking information are made as of the date hereof and are qualified in their entirety by this cautionary statement. The Company disclaims any obligation to revise or update any such factors or to publicly announce the result of any revisions to any forward-looking statements or forward looking information contained herein to reflect future results, events or developments, except as require by law. Accordingly, readers should not place undue reliance on forward-looking statements and information. Please refer to the Company’s most recent filings under its profile at www.sedar.com for further information respecting the risks affecting the Company and its business.